Over the past year, advancements in thermal imagery have significantly emerged in the field of predictive maintenance. Researchers uncovered a new lens material that substantially reduced the cost of lens systems. Additionally, in early February, a team of scientists at Purdue conducted studies resulting in the development of highly sophisticated thermal imagery cameras, offering enhanced features compared to traditional bulky models. Furthermore, a notable solution provider has made strides in advanced thermal imagery by introducing a camera that incorporates Artificial Intelligence to enhance performance.

Thermal imagery has made significant strides in the past year, finding applications in various fields such as medicine, defense, space exploration, and electrical engineering. Its potential also extends to predictive maintenance, offering promising prospects for anomaly detection and prediction.

Here’s how advanced thermal imaging is revolutionizing the predictive maintenance field:

Advancement in Thermal Imagery and Predictive Maintenance

Predictive maintenance technology is crucial to asset management, especially for product manufacturing, power generation, and municipality sectors. These areas operate with critical machinery, which, in case of failure, could compromise the safety and financial stability of the whole plant. To keep these machines operational, predictive maintenance solutions must be regularly provided to assess the machine’s health.

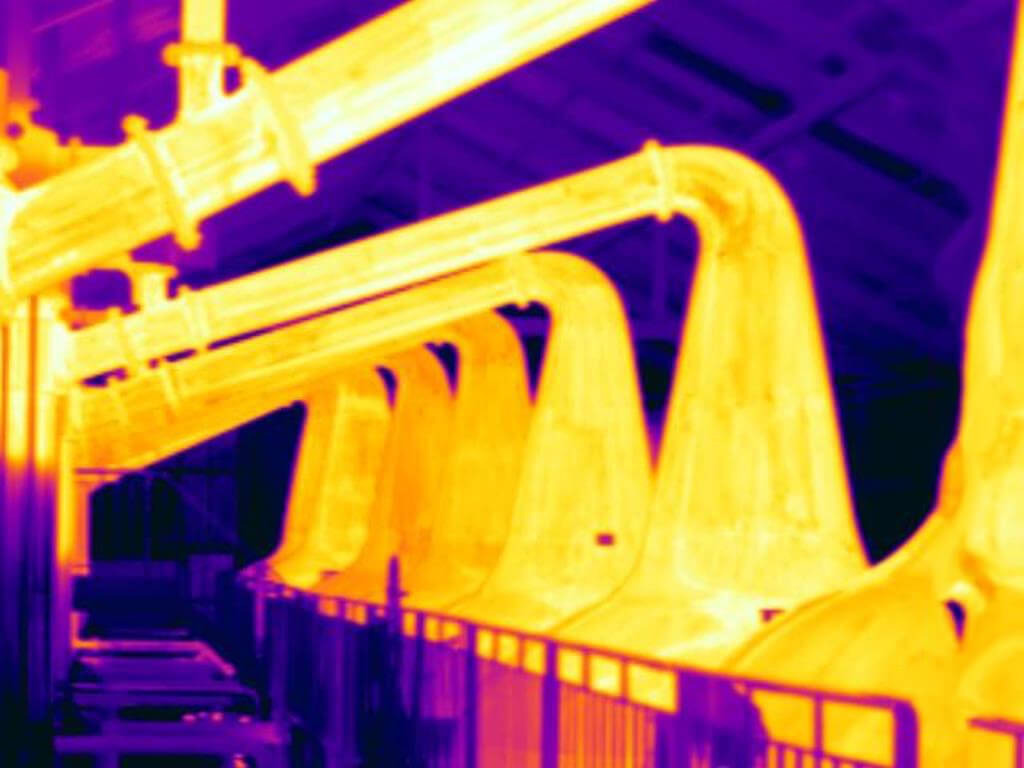

Thermal imaging is among the common practice when it comes to evaluating the internal components of machines. Heat anomalies are a common indicator of potential issues. It signifies that internal issues require immediate attention; otherwise, they could lead to unwanted downtime and machine failure.

Advancement in thermal imagery could be a stepping stone to improve thermal imaging practice. Lens material upgrades could help reduce thermal imaging costs and allow it to fall into an affordable scale. In addition, with the developments made in the model allowing it to reduce in size, it can assist in getting info from hard-to-reach areas. In addition, as AI practices are integrated, it can allow better visualization of machines and monitor temperature changes more accurately. This would help with predictive maintenance as it will also provide better results, which can assist in more accurate predictions.

Integrating these new technological advancements can streamline predictive maintenance operations, improving plant operations.

Final Note:

In conclusion, advancement in thermal imagery has shown advancements in leaps and bounds, providing a positive outlook for the predictive maintenance industry. These advancements can also benefit organizational efficiency and streamline operations. In addition to thermal imagery, manufacturing plants and other sectors handling critical machinery must adopt various predictive maintenance practices to optimize machine performance. Also read this blog to have an idea about thermal imaging equipment.