The recent news regarding fire safety concerns raised by the Detroit Fire Department at General Motors (GM) Factory Zero, a facility dedicated to electric vehicle (EV) production, has sparked important conversations about safety in the rising EV industry. While lithium-ion batteries do show a promising future in electric transportation, they also pose unique fire risks.

Here at Condition Monitoring Technologies, we believe that predictive maintenance systems, particularly thermal imaging solutions, can be critical in preventing these incidents before they escalate.

The December 2023 fire at Factory Zero, involving burning pallets of lithium-ion batteries, is a stark reminder of the potential dangers associated with EV production. According to the Detroit Free Press, this wasn’t an isolated episode, with the Detroit Fire Department responding to the facility eight times since last summer. These incidents highlight the urgent need for proactive measures to ensure the safety of workers, facilities, and surrounding communities.

The Challenge that Comes with EV Production

Unlike traditional combustion engines, EV batteries don’t exhibit the same warning signs of impending failure, such as smoke or leaks. This makes early detection of potential issues crucial. It may be too late to prevent significant damage and risk when a fire becomes readily apparent.

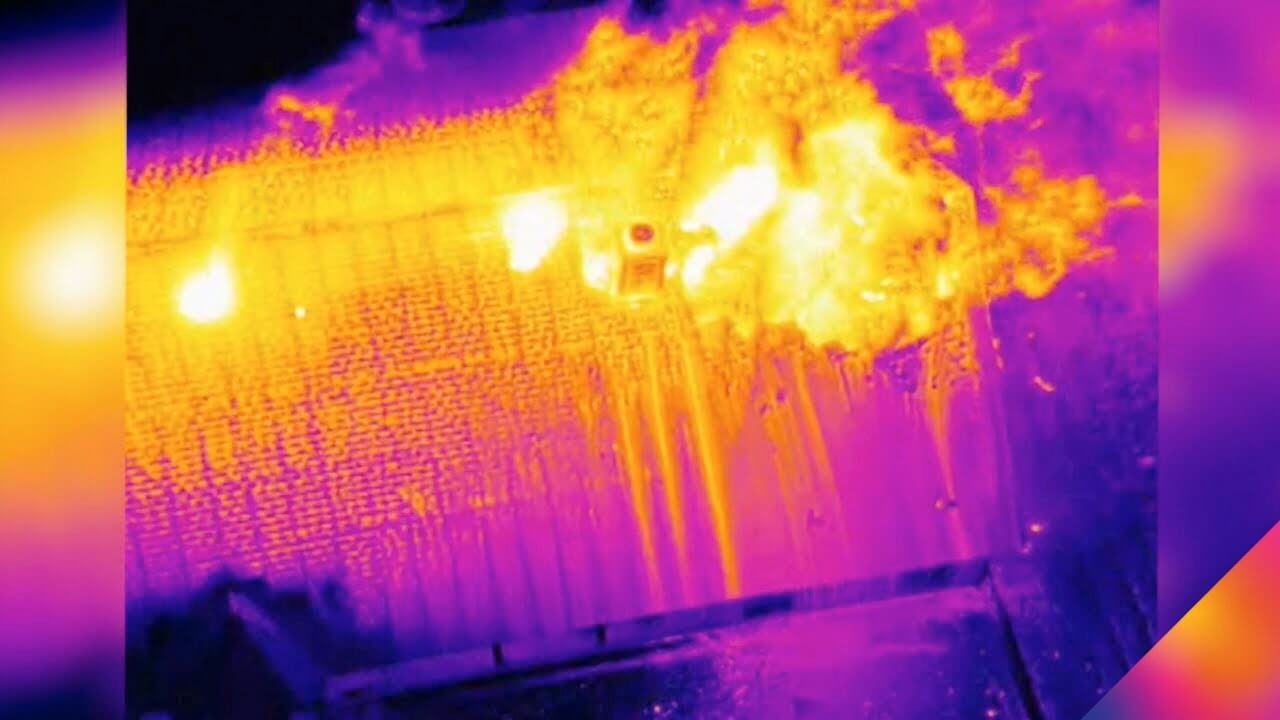

Thermal Imaging Helps View the Unseen

This is where thermal imaging solutions step in. Thermal cameras are a sixth sense for maintenance teams, detecting areas with abnormal heat signatures that may indicate malfunctioning battery cells or overheating equipment. These “hot spots” can be identified well before a fire ignites, allowing for targeted maintenance and intervention.

Here’s a closer look at the benefits of using thermal imaging in EV manufacturing facilities:

1. Proactive Problem Identification

Thermal cameras can detect subtle temperature changes, revealing potential problems long before catastrophic failures occur.

2. Enhanced Safety Measures

Early detection allows for preventative maintenance, addressing the issue and preventing a fire from occurring in the first place. This translates to a safer working environment for employees and minimizes the risk of firefighters needing to enter hazardous situations during an active fire.

3. Reduced Downtime

By identifying and addressing potential problems before they cause a breakdown, thermal imaging helps to ensure production lines run smoothly, minimizing costly downtime from fire incidents.

4. Environmental Protection

EV battery fires can release harmful toxins into the environment. By preventing fires, thermal imaging also minimizes potential environmental damage.

Apart from Thermal Imaging

While thermal imaging plays a vital role, it’s important to emphasize that it’s just one piece of the puzzle. At Condition Monitoring Technologies, we offer a complete suite of predictive maintenance solutions tailored to the specific needs of production facilities. This includes:

1. Vibration Analysis

Vibration monitoring can detect imbalances, misalignment, and bearing wear in rotating equipment, potentially leading to overheating and, ultimately, fires.

2. Ultrasonic Testing

This non-destructive testing technique can identify cracks, voids, and other defects in critical components, ensuring their integrity and preventing potential failures.

Partnering for a Safer Future

Our team of experienced engineers can comprehensively evaluate critical machinery operating within your facility. By combining these technologies, we can assess the overall health of your equipment and recommend the most appropriate maintenance strategies to prevent failures and ensure optimal performance.

Final Note

Ultimately, by implementing a robust predictive maintenance program incorporating thermal imaging solutions alongside others, EV manufacturers like GM’s Factory Zero can significantly enhance fire safety, reduce downtime, and minimize environmental risks. This proactive approach protects the well-being of employees and the surrounding community and contributes to the long-term success and sustainability of the EV industry.